Awe-Inspiring Examples Of Info About What Is The Difference Between PTC And NTC PT100

Understanding Temperature Sensors

1. What's the Buzz About Temperature Sensing?

Ever wonder how your thermostat knows when to kick on the heat or your car's engine knows when to cool down? The answer often lies in tiny devices called temperature sensors. These little wizards translate temperature changes into electrical signals, allowing machines to "feel" the heat (or lack thereof!). Among the most common types are PTC, NTC, and PT100 sensors. But what exactly are they, and what's the real difference between them? Lets dive in and demystify these temperature-sensing components, shall we?

Imagine you're baking a cake (or trying to, anyway!). You need to know the oven temperature to avoid a culinary disaster. Similarly, many industrial and everyday applications require precise temperature monitoring. These sensors are the unsung heroes, ensuring processes run smoothly and safely.

We'll break down each type — PTC, NTC, and PT100 — looking at how they work, where they're typically used, and what makes each one unique. Consider it a friendly guide to understanding these essential components. By the end, you'll be able to confidently tell your PTCs from your NTCs and perhaps even impress your friends with your newfound temperature-sensing knowledge! Maybe. At least you'll be able to explain why your coffee maker works, right?

And don't worry, we'll keep it relatively jargon-free. Think of it as a casual conversation, not a technical lecture. So, grab your beverage of choice, and let's get started!

What Is Difference Between PTC & NTC YouTube

PTC

2. How PTC Thermistors Work

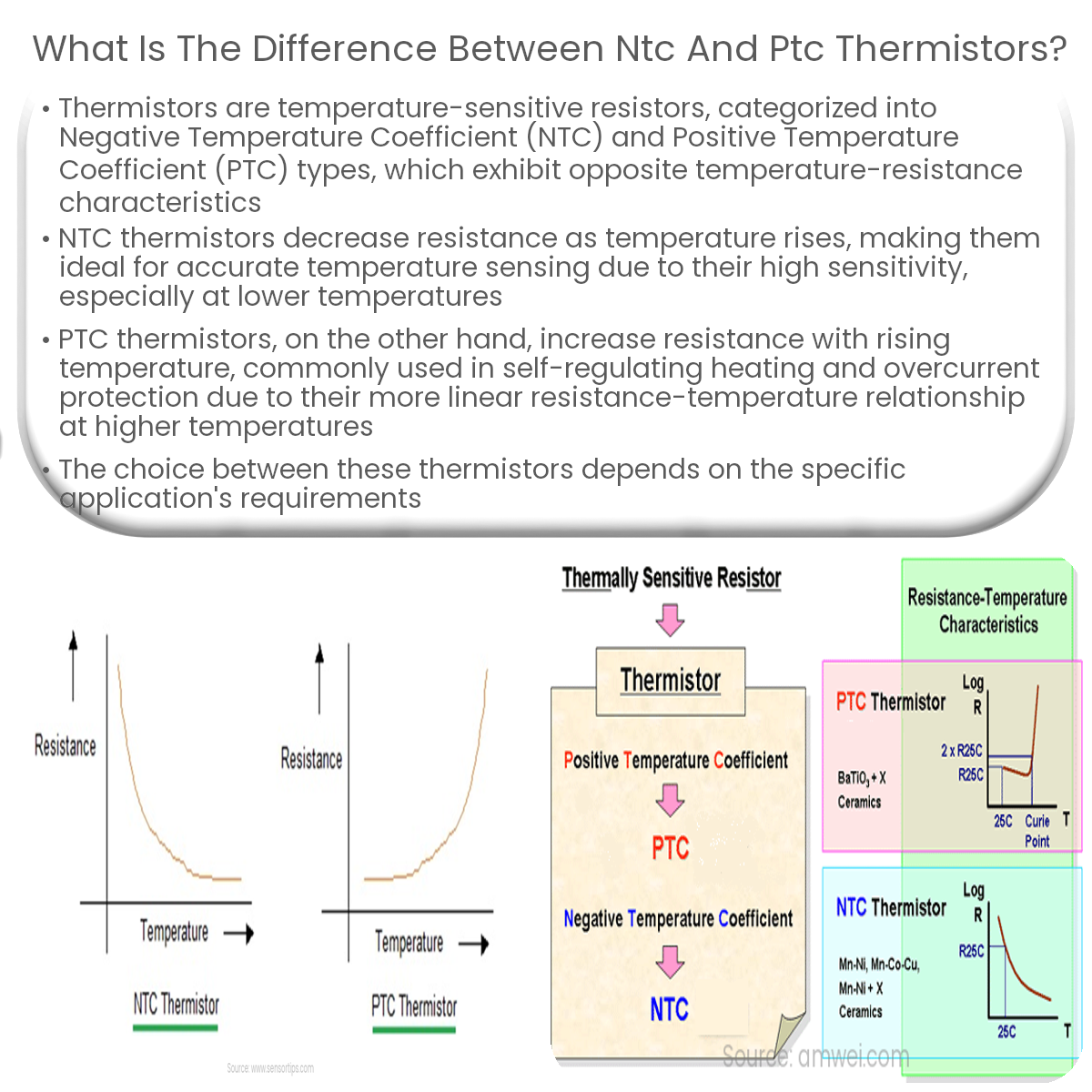

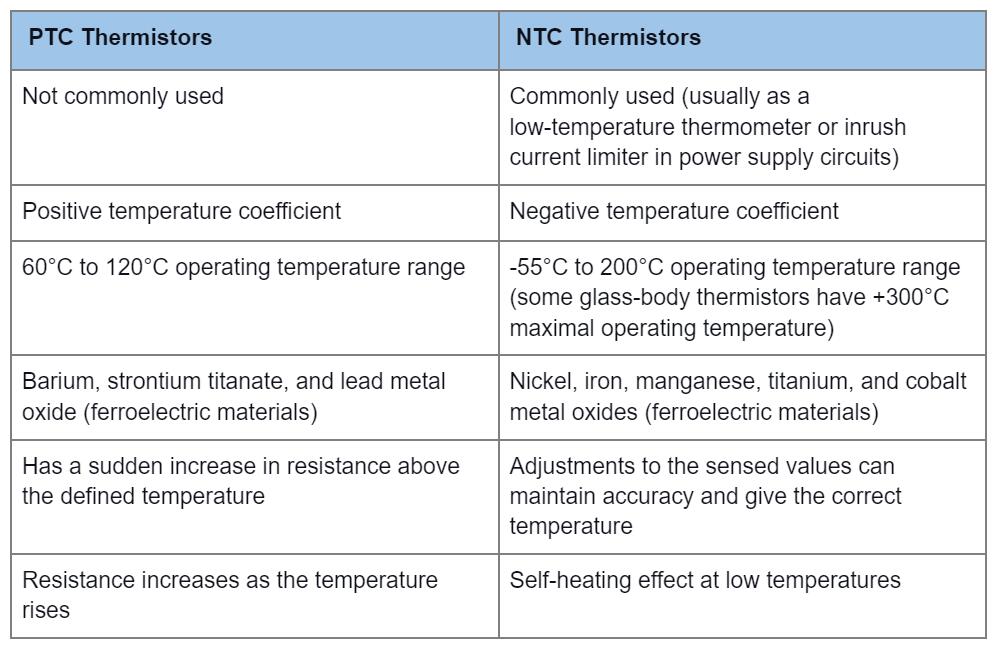

PTC stands for Positive Temperature Coefficient. This essentially means that as the temperature increases, the resistance of the thermistor also increases. Think of it like this: the hotter it gets, the more the PTC "resists" the flow of electricity. It's a simple yet effective principle that has various applications.

Now, the interesting thing about PTC thermistors is that they don't increase linearly. Up to a certain temperature (called the Curie temperature or switching temperature), the resistance remains relatively low. But once it hits that Curie temperature, the resistance shoots up dramatically! This sudden change in resistance makes PTC thermistors particularly useful for overcurrent protection and self-regulating heaters.

Consider a lightbulb filament. Without some form of protection, a surge of electricity could easily burn it out. A PTC thermistor in series with the lightbulb can limit the current by increasing its resistance when it gets too hot, preventing the dreaded "pop!" It's like a tiny, heat-sensitive bodyguard for your electronics.

PTC thermistors are also used in some self-regulating heaters. As the heater warms up, the PTC's resistance increases, limiting the current and preventing it from overheating. This makes them a safer and more energy-efficient alternative to traditional heaters. So, the next time you're enjoying the warmth of a self-regulating heater, remember the PTC thermistor working behind the scenes.

NTC

3. NTC Thermistors

NTC stands for Negative Temperature Coefficient. As you might have guessed, this is essentially the opposite of a PTC. With NTC thermistors, as the temperature increases, the resistance decreases. The hotter it gets, the easier it is for electricity to flow through.

Unlike PTCs, NTC thermistors have a much more gradual resistance change compared to PTC thermistors, there is not a sudden "jump" at a specific temperature like PTCs. The relationship is generally exponential and more predictable, this makes NTC thermistors a better choice for temperature measurement applications.

NTC thermistors are widely used for temperature measurement and control. They're found in everything from thermometers and HVAC systems to car engine coolant sensors and 3D printer heated beds. Their high sensitivity and relatively fast response time make them ideal for these applications. They're like the sensitive and responsive thermometers of the electronic world.

For example, in a car engine, an NTC thermistor monitors the coolant temperature. The engine control unit (ECU) uses this information to adjust the fuel injection and ignition timing, optimizing engine performance and reducing emissions. Without the NTC thermistor, the engine wouldn't know how hot it was getting, leading to poor fuel economy, increased emissions, and potentially even engine damage.

What Is The Difference Between PTC And PT100 Product Knowledge

PT100

4. PT100 Sensors

Now, let's move on to PT100 sensors. PT stands for Platinum, and 100 refers to the resistance in ohms at 0C. These sensors belong to a class of temperature sensors called Resistance Temperature Detectors (RTDs). Unlike thermistors, RTDs use a metal (usually platinum) whose resistance changes linearly with temperature. This linearity makes them highly accurate and stable over a wide temperature range.

The basic principle behind a PT100 sensor is that the resistance of platinum changes predictably with temperature. The higher the temperature, the higher the resistance. This relationship is well-defined and consistent, making PT100 sensors suitable for precision temperature measurement in industrial and laboratory settings.

PT100 sensors are known for their accuracy, stability, and repeatability. They can measure temperatures from -200C to +600C with high precision. However, they're also more expensive and slower to respond to temperature changes than thermistors. They're like the reliable and accurate veterans of the temperature-sensing world, even if they're not the fastest.

These sensors are commonly used in industries such as chemical processing, food processing, and pharmaceutical manufacturing, where precise temperature control is essential. You'll find them in everything from temperature baths and calibration equipment to industrial ovens and HVAC systems. They are the standard when accuracy and repeatability are paramount, ensuring process parameters are precisely maintained for consistent quality and safety.

PTC Thermistor Temperature Sensitive Resistors For Electronic Circuit

Key Differences Summarized

5. PTC vs. NTC vs. PT100

So, to recap the key differences between PTC, NTC, and PT100 sensors: PTC thermistors increase in resistance as temperature increases, useful for overcurrent protection and self-regulating heaters. NTC thermistors decrease in resistance as temperature increases, suitable for temperature measurement and control. PT100 sensors use platinum to provide accurate, stable, and linear temperature measurements over a wide range, but are generally more expensive and slower. Each has its strengths and weaknesses, making them suitable for different applications.

Ultimately, the choice between PTC, NTC, and PT100 sensors depends on the specific application requirements. Consider the temperature range, accuracy, response time, and cost when selecting the right sensor for the job. A quick reference table might help:

Here's a small summary:

- PTC: Resistance increases with temperature; good for protection.

- NTC: Resistance decreases with temperature; good for measurement.

- PT100: Platinum-based; accurate, stable, but pricier.

Understanding the differences between these temperature sensors can make all the difference in ensuring the proper functionality and reliability of your devices and systems. So, the next time you're faced with a temperature-sensing challenge, you'll be well-equipped to make the right choice.

What Is The Difference Between PTC And PT100 Product Knowledge

Applications In Depth

6. Where You'll Find Them

Let's delve a little deeper into some specific applications to illustrate how these sensors are used in practice. In your home, an NTC thermistor might be monitoring the temperature inside your refrigerator, ensuring that your food stays fresh without freezing. A PTC thermistor could be protecting the circuits in your power adapter, preventing damage from overcurrent situations. These are all commonplace and relatively inexpensive applications.

Moving into the industrial realm, consider a chemical processing plant where precise temperature control is critical for safety and product quality. PT100 sensors are often used in reactors and pipelines to monitor and maintain optimal temperatures, ensuring that chemical reactions proceed as intended and preventing hazardous situations. The reliability and accuracy of PT100 sensors make them indispensable in these environments, where even small deviations in temperature can have significant consequences.

Furthermore, in the automotive industry, you'll find a combination of these sensors working together to optimize engine performance and emissions. NTC thermistors are used to monitor coolant temperature, air intake temperature, and exhaust gas temperature, providing valuable data to the engine control unit (ECU). The ECU uses this information to fine-tune fuel injection, ignition timing, and other parameters, maximizing fuel efficiency, reducing emissions, and ensuring smooth engine operation. In some cases, PTC thermistors may be used for overcurrent protection in electrical systems.

From the everyday convenience of household appliances to the critical precision of industrial processes, PTC, NTC, and PT100 sensors play essential roles in various applications. Understanding their strengths and limitations enables engineers and designers to select the right sensor for the job, optimizing performance, reliability, and safety.