Marvelous Info About What Is The Difference Between PI And PR Controller

Decoding PI and PR Controllers

1. Understanding the Basics

So, you've stumbled upon the world of control systems and heard whispers of PI and PR controllers. Don't worry, you're not alone! These aren't some secret society handshake signals, but rather control algorithms designed to keep systems behaving nicely. Think of them as tiny digital maestros, orchestrating processes to achieve the desired outcome. The trick is knowing when to use a proportional-integral (PI) conductor versus a proportional-resonant (PR) driver for the best results.

At their core, both PI and PR controllers aim to minimize the error between a desired setpoint and the actual output of a system. That setpoint, by the way, is just the target value you want to achieve think the temperature in your oven, the speed of a motor, or the voltage in a power supply. Now, how do they achieve this error-reducing magic?

Both use proportional control, which reacts directly to the size of the error. The larger the error, the stronger the corrective action. Imagine you're steering a car, and you start drifting to the right. Proportional control is like turning the wheel back to the left — the further you drift, the harder you turn. But proportional control alone often isn't enough; it can leave a steady-state error. That's where the 'I' and the 'R' come in.

The beauty of a well-tuned control system is how smoothly it can maintain the desired setpoint. It's a bit like walking a tightrope. To get to the other side you need to constantly adjust your balance. PI and PR controllers are designed to do just that - constantly adjust until there is no more error.

(PDF) Comparison Between Fractional Order PI Controller And SIMC

The PI Controller

2. Integral Action to the Rescue

The 'I' in PI stands for "integral." This part of the controller looks at the history of the error. It accumulates the error over time and applies a correction proportional to this accumulation. The integral action diligently chips away at any remaining steady-state error. Think of it as a persistent, meticulous housekeeper, forever dusting away any lingering dirt (or error, in this case).

Let's say your oven is consistently running a few degrees below the set temperature using only proportional control. The integral action in a PI controller would notice this consistent, albeit small, error. It would gradually increase the heat output until the oven finally reaches and maintains the correct temperature.

PI controllers are widely used in applications where a constant setpoint needs to be maintained, and slow changes are expected. Temperature control, speed regulation, and liquid level control are prime examples. They're the workhorses of industrial automation, keeping things humming along smoothly and efficiently.

However, it's important to remember that too much integral action can lead to oscillations or even instability. The controller might overcorrect, then undercorrect, then overcorrect again, leading to a jerky, undesirable response. Tuning the integral gain carefully is crucial to achieve optimal performance. The struggle is real!

Pin On Elektronika

The PR Controller

3. Resonance

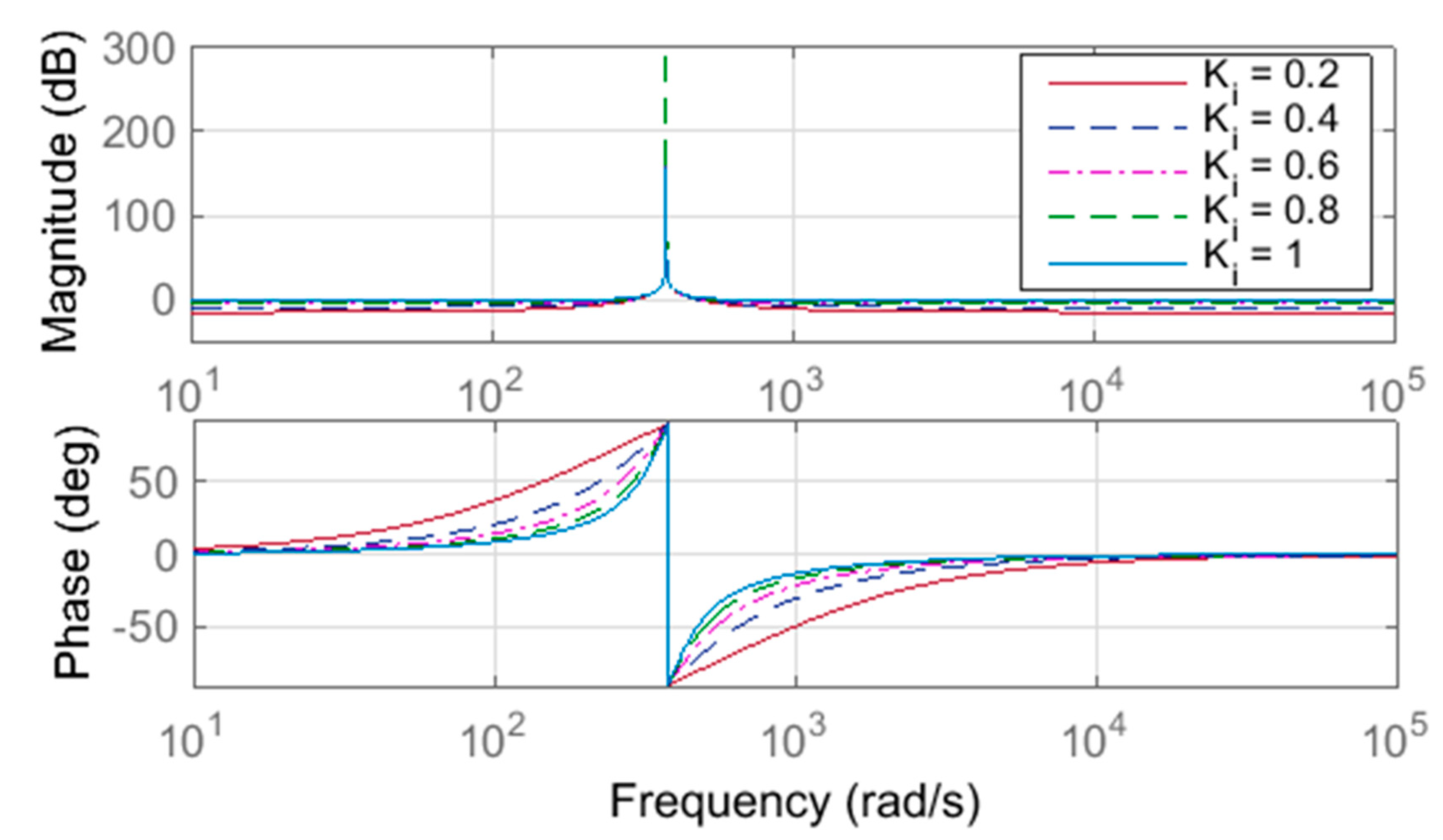

Now, enter the PR controller. The 'R' stands for "resonant." This controller is specifically designed to eliminate errors associated with sinusoidal signals — signals that oscillate at a particular frequency. Think of it like tuning a radio to a specific station. The resonant part of the controller amplifies the response to that frequency, effectively canceling out any errors at that frequency.

Consider a grid-tied inverter, which needs to inject current into the power grid in perfect synchronisation with the grid voltage. Any phase or amplitude error in the injected current can lead to inefficiencies and even instability. A PR controller, tuned to the grid frequency (e.g., 50 Hz or 60 Hz), can precisely eliminate these errors, ensuring seamless and efficient power transfer.

PR controllers are particularly useful for applications involving AC systems, such as motor drives, active power filters, and grid-connected converters. They excel at tracking and rejecting periodic disturbances, leading to improved performance and stability. Imagine you're trying to balance on a wobbly platform; PR controllers are like having a built-in gyroscope that automatically counteracts the wobble.

Just like with PI controllers, proper tuning is essential. The resonant frequency must be accurately tuned to the frequency of the signal being controlled. Mismatches can lead to poor performance or even instability. This is why a resonant controller is usually found where the frequency is well-known, for example, with AC power.

PID Controller, P, I And D Control Comparison PI, PD Controller

PI vs. PR

4. Picking the Right Tool for the Job

So, how do you decide whether to use a PI or a PR controller? The key lies in understanding the nature of the signal you're trying to control. If you're dealing with a relatively constant setpoint and slow variations, a PI controller is usually the best choice. If you're dealing with sinusoidal signals or periodic disturbances, a PR controller is the way to go. Choosing the right controller will help you get your desired results from the system.

Think of it this way: PI controllers are like general-purpose wrenches, useful for a wide range of tasks. PR controllers are like specialized wrenches, designed for a specific type of nut. You could try using a general-purpose wrench on that specific nut, but you'll probably get a much better (and faster) result with the specialized tool.

Another factor to consider is the complexity of implementation. PI controllers are relatively simple to implement and tune. PR controllers are a bit more complex, requiring careful tuning of the resonant frequency. In some cases, a combination of PI and PR control may be used to achieve optimal performance.

Essentially, if the goal is to eliminate steady-state error for DC signals, PI is the king. If the goal is to eliminate steady-state error for AC signals, PR is the champion. But beware, like every champion, PR controllers need careful training (tuning) to perform at their peak!

Beyond the Basics

5. Diving Deeper into Control System Design

While PI and PR controllers are powerful tools, they're not always the perfect solution for every control problem. More advanced control techniques, such as model predictive control (MPC) or adaptive control, may be necessary for complex systems with nonlinearities, time delays, or disturbances.

Model predictive control, for example, uses a model of the system to predict its future behavior and optimize the control actions accordingly. Adaptive control, on the other hand, adjusts the controller parameters in real-time to compensate for changes in the system or environment. These techniques can provide superior performance in challenging situations.

Another important consideration is the implementation of the controller in hardware or software. Digital controllers, implemented in microcontrollers or digital signal processors (DSPs), are widely used due to their flexibility and programmability. Analog controllers, implemented using operational amplifiers and other analog components, may be preferred in some applications due to their speed and simplicity.

The world of control systems is vast and fascinating. Mastering PI and PR controllers is a great starting point, but there's always more to learn. So, keep exploring, keep experimenting, and keep pushing the boundaries of what's possible!

Python Control Pole Placement At Marilyn Roslyn Blog

Frequently Asked Questions (FAQ)

6. Your Burning Questions Answered

Let's tackle some common questions about PI and PR controllers:

Q: Can I use a PI controller for an AC motor drive?A: While you can use a PI controller for an AC motor drive, it's generally not the best choice for current control. PR controllers are often preferred because they can more effectively eliminate errors at the fundamental frequency of the AC signal. However, PI controllers can still be useful for speed control or other outer loops in the drive system.

Q: What happens if the resonant frequency of a PR controller is not perfectly tuned?A: If the resonant frequency is misaligned, the controller's performance will degrade. It won't be as effective at eliminating errors at the desired frequency, and it may even introduce oscillations or instability. Precise tuning is crucial for optimal performance. There are usually software to fine tune and correct frequency

Q: Are there any disadvantages to using PR controllers?A: Yes, PR controllers can be more sensitive to noise and disturbances than PI controllers. They also require careful tuning and can be more complex to implement. However, the benefits they offer in terms of tracking and rejecting periodic signals often outweigh these drawbacks.