One Of The Best Tips About Why IGBT Is Better Than MOSFET

MOSFET Vs IGBT Project

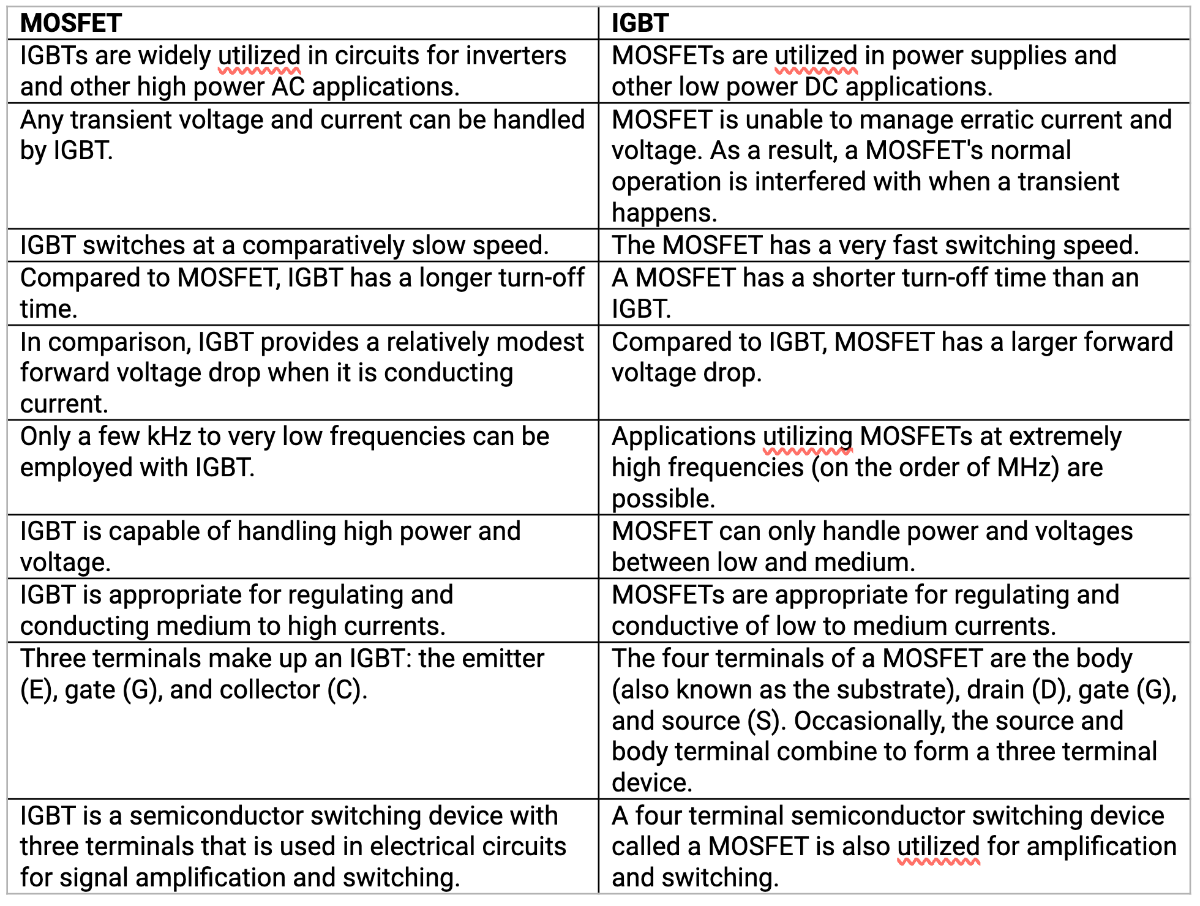

IGBT vs. MOSFET

1. Understanding the Players

Alright, let's talk transistors! Specifically, we're diving into the world of MOSFETs and IGBTs. Now, I know what you might be thinking: "Transistors? Sounds boring!" But trust me, these little guys are the unsung heroes of modern electronics. They're like tiny switches that control the flow of electricity, powering everything from your phone to your refrigerator. So, buckle up, because we're about to explore why, in certain situations, the IGBT reigns supreme over the MOSFET. Think of it as a heavyweight boxing match, but with electrons.

MOSFET, which stands for Metal-Oxide-Semiconductor Field-Effect Transistor, are known for their fast switching speeds and relatively simple operation. Theyre the sprinters of the transistor world, quickly turning on and off. This makes them ideal for applications that require high frequencies, like switching power supplies in your laptop or controlling the brightness of an LED screen. They handle lower voltages and currents with grace, making them efficient for smaller tasks.

Now, enter the IGBT, or Insulated Gate Bipolar Transistor. This is a hybrid device, combining the best features of MOSFETs and bipolar junction transistors (BJTs). It's like a powerlifter — built for handling high voltages and currents. While it might not be as nimble as a MOSFET, it can certainly pack a punch when it comes to delivering serious power. The IGBT shines in scenarios where you need to control a large motor, like in an electric car or an industrial machine.

So, to keep it simple: MOSFETs are fast and efficient for low-power applications, while IGBTs are robust and capable for high-power demands. But, what happens when these two face off in the real world? Keep reading and we'll see!

The Power Struggle

2. High Voltage & Current Handling

Here's the deal: When it comes to sheer muscle, the IGBT flexes harder than the MOSFET. Imagine trying to power a Tesla. You wouldn't use a bunch of tiny MOSFETs, right? You need something that can handle the high voltages and massive currents required to get that electric beast moving. That's where the IGBT comes in. Its internal structure is designed to withstand these extreme conditions, making it perfect for applications like electric vehicle inverters, high-power motor drives, and even welding equipment. Think of it as the workhorse of the power electronics world.

MOSFETs, on the other hand, start to struggle at higher voltages. Their on-resistance (the resistance when the transistor is "on") increases significantly, leading to greater power loss and heat generation. This isn't ideal when you're trying to be efficient and avoid melting your components. IGBTs have a lower on-resistance at high voltages, meaning they can deliver more power with less wasted energy. That's a big win in terms of efficiency and reliability.

This isn't to say MOSFETs are completely useless at higher voltages, it's just that they become less efficient. Think of it like trying to run a marathon in flip-flops. Sure, you could do it, but you'd be much better off with proper running shoes (or, in this case, an IGBT).

So, when the power demands are high and the stakes are even higher, the IGBT steps up to the plate, ready to deliver the knockout punch.

Difference Between IGBT And MOSFET

Switching Speed and Efficiency

3. A Delicate Balance

Okay, so we've established that IGBTs are powerhouses. But what about speed? This is where the MOSFET starts to regain some ground. MOSFETs are generally faster than IGBTs when it comes to switching on and off. This makes them great for applications that require rapid switching, like high-frequency power supplies.

However, the switching speed advantage of MOSFETs comes with a caveat. Faster switching can lead to increased switching losses, especially at higher voltages and currents. This is because it takes energy to charge and discharge the gate capacitance of the MOSFET, and this energy is dissipated as heat during each switching cycle. This isn't a problem at lower power levels, but it can become significant at higher power levels, where IGBTs dominate.

IGBTs, while not as fast as MOSFETs, have been steadily improving their switching speeds over the years. Modern IGBTs offer a good compromise between switching speed and power handling capability. They can switch fast enough for many applications without sacrificing efficiency. In many high-power applications, the slower switching speed of the IGBT is a reasonable trade-off for its superior voltage and current handling capabilities.

Ultimately, the best choice between MOSFET and IGBT depends on the specific application. If you need lightning-fast switching and can tolerate some power loss, the MOSFET is the way to go. But if you need to handle high voltages and currents with minimal power loss, the IGBT is the better choice. It's all about finding the right balance between speed and efficiency.

Cost Considerations

4. The Price of Power

Let's talk about money. In general, MOSFETs tend to be more cost-effective than IGBTs, especially for lower power applications. This is because MOSFETs are simpler to manufacture and have been around for a longer time, making them readily available and relatively inexpensive. If you're building a simple circuit that doesn't require a lot of power, a MOSFET might be the best option for your wallet.

However, as the power requirements increase, the cost difference between MOSFETs and IGBTs starts to narrow. To achieve comparable performance at higher voltages and currents, you might need to use multiple MOSFETs in parallel, which can drive up the cost and complexity of the circuit. In these cases, a single IGBT might be a more cost-effective solution. It's like buying one powerful tool versus several smaller ones to accomplish the same heavy-duty task. It will make it easier and less costly.

Furthermore, consider the overall system cost. While a MOSFET might be cheaper upfront, it might require more sophisticated cooling solutions to handle the heat generated by switching losses at higher power levels. An IGBT, with its lower on-resistance and better thermal performance, might require a simpler and less expensive cooling system, ultimately reducing the total system cost. It's more than just the cost of the component itself; it's about the cost of all the supporting components and the long-term operational costs.

So, while MOSFETs might have a lower initial price tag, it's important to consider the total cost of ownership when making your decision. In many high-power applications, the IGBT's superior performance and efficiency can make it the more cost-effective choice in the long run. It's all about doing your homework and understanding the specific requirements of your application.

How Does An IGBT Work? Meaning & Structure CircuitBread

Real-World Applications

5. Seeing is Believing

Okay, we've talked theory, now let's get practical. Where do you actually find these transistors in action? MOSFETs are everywhere in low-power applications: your smartphone, laptop, and most consumer electronics rely on them for their efficient and speedy switching capabilities. They control the backlight of your screen, manage power distribution, and switch signals throughout the device. Think of them as the tiny worker bees buzzing inside your gadgets.

IGBTs, on the other hand, are the heavy lifters in high-power systems. You'll find them in electric cars, controlling the motors and inverters that propel these vehicles. They're also used in industrial motor drives, welding machines, and even some high-end audio amplifiers. They're the ones handling the grunt work, delivering the massive power needed to drive these applications. You will find them in renewable energy system. Example in solar power inverters for converting DC electricity from solar panel and convert it to AC electricity to use in houses.

Consider a variable frequency drive (VFD) used to control the speed of an industrial motor. The VFD uses IGBTs to switch the power to the motor at different frequencies, allowing precise control over the motor's speed and torque. This is crucial in applications like conveyor belts, pumps, and fans, where precise control is essential for efficiency and productivity. It's like having a finely tuned throttle for your industrial machinery.

Ultimately, the choice between MOSFET and IGBT depends on the specific application and its power requirements. If you're designing a small, battery-powered device, a MOSFET is probably the way to go. But if you're building a high-power inverter or a motor drive, an IGBT is likely the better choice. Understanding the strengths and weaknesses of each transistor is key to designing a successful and efficient system. So, next time you see an electric car zoom by, remember the IGBTs working hard under the hood!

FAQ

6. Your Burning Questions Answered!

Q: When should I definitely use an IGBT over a MOSFET?A: If your application involves high voltages (typically above 600V) and significant current levels, an IGBT is generally the better choice. It's designed to handle these conditions efficiently and reliably, whereas a MOSFET might struggle with increased power loss and heat generation. Think of it as choosing the right tool for the job: a hammer for nails, and an IGBT for high-power applications!

Q: Are IGBTs always slower than MOSFETs?A: Generally, yes. MOSFETs tend to have faster switching speeds than IGBTs. However, modern IGBTs have significantly improved their switching speeds, making them suitable for many applications. It's important to consider the specific requirements of your application and choose a transistor that offers the best balance between speed and efficiency.

Q: Can I replace a MOSFET with an IGBT in any circuit?A: Not necessarily. While both are transistors, they have different characteristics and require different driving circuitry. You'll need to carefully consider the voltage and current requirements, switching speed, and gate drive characteristics of your circuit before making a substitution. It's always best to consult the datasheets for both devices to ensure compatibility and proper operation.