Awe-Inspiring Examples Of Tips About CAN Bus Vs PROFIBUS

What Is The Difference Between Profibus And Vs

CAN bus vs PROFIBUS

1. Understanding the Basics

Ever felt like you're drowning in alphabet soup when talking about industrial communication? CAN bus and PROFIBUS are two big players in this arena, each with its own strengths and quirks. It's like comparing a reliable pickup truck to a speedy sports car — both can get you from A to B, but how they do it and where they excel are vastly different. So, let's dive in and untangle these technologies without getting bogged down in overly technical details. We'll explore their core principles and some real-world examples.

Think of CAN bus (Controller Area Network bus) as a highly efficient messaging system for your car, but on a much larger industrial scale. Its designed for robust, real-time communication between different microcontrollers and devices. Imagine your car's engine control unit (ECU) chatting with the anti-lock braking system (ABS) — that's CAN bus in action. Its particularly good at handling critical data that needs to be transmitted reliably and quickly.

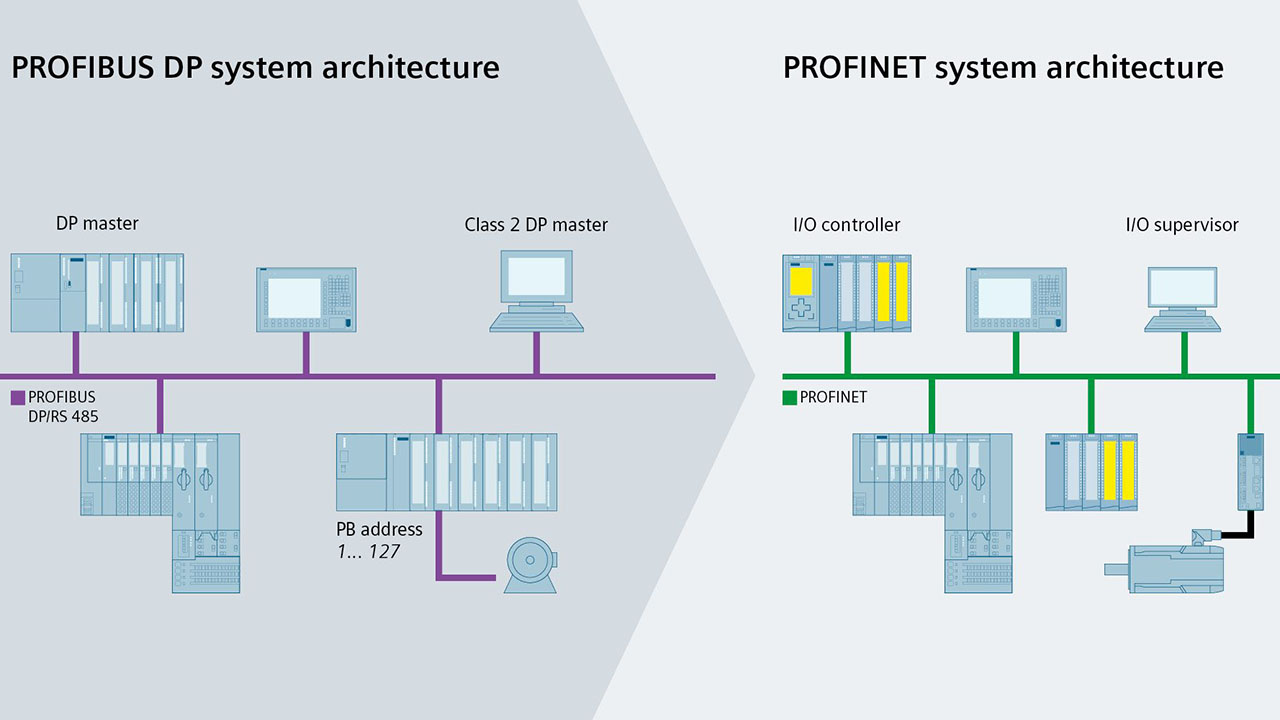

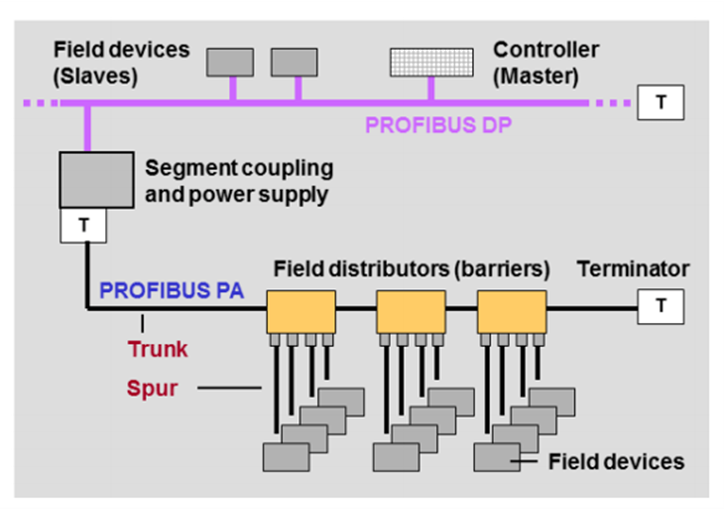

Now, PROFIBUS (Process Field Bus) is more like a well-organized network connecting a wide range of field devices like sensors, actuators, and programmable logic controllers (PLCs). It's commonly used in factory automation and process control applications. Picture a sprawling manufacturing plant where hundreds of devices need to coordinate their actions seamlessly. PROFIBUS comes in several flavors, each tailored to different needs and environments.

Choosing between CAN bus and PROFIBUS depends heavily on the specific application. Its not about which is inherently "better," but rather which is the best fit for the job at hand. Are we talking about tightly coupled, real-time control within a machine, or a broader network connecting numerous devices across a large plant? The answer to that question will greatly influence the optimal choice.

Key Differences and When to Use Each

2. Dissecting the Details

Alright, let's get a bit more specific. CAN bus is a broadcast-oriented protocol, meaning that all devices on the network "hear" every message. However, only the device with the matching identifier acts upon it. This ensures efficient communication without the need for a central master controller. This decentralized approach is perfect for applications where reliability and speed are paramount, such as automotive systems, medical equipment, and some embedded control systems.

PROFIBUS, on the other hand, typically operates in a master-slave configuration. One or more master devices (usually PLCs) control the communication with slave devices (sensors, actuators, etc.). This hierarchical structure is well-suited for larger, more complex automation systems where a central controller needs to coordinate the actions of many field devices. Think of it as a well-managed orchestra, with the conductor (PLC) directing the various instruments (sensors and actuators).

Another key difference lies in the physical layer. CAN bus commonly uses a twisted-pair cable and differential signaling, which makes it robust against noise and interference. PROFIBUS offers a wider range of physical layers, including shielded twisted-pair cable (RS-485) and fiber optics, allowing it to be adapted to various environments and distances.

Essentially, if you need robust, real-time communication within a limited area, CAN bus is often the way to go. If you're building a large-scale automation system with numerous devices and varying communication requirements, PROFIBUS might be a better choice. Consider factors like data rate, distance, network topology, and cost when making your decision.

Advantages and Disadvantages

3. Weighing the Pros and Cons

Every technology has its ups and downs, and CAN bus and PROFIBUS are no exception. Let's take a look at some of the key advantages and disadvantages of each.

CAN bus shines in its simplicity, robustness, and low cost. Its decentralized architecture makes it highly resilient to single-point failures. If one device goes down, the rest of the network can continue to function. However, CAN bus is limited in terms of bandwidth and network size compared to PROFIBUS. It's also less flexible in terms of network topology and device types.

PROFIBUS offers greater flexibility and scalability. It can support a wider range of devices and network topologies, and it can handle larger amounts of data. However, PROFIBUS is typically more complex and expensive to implement than CAN bus. Its master-slave architecture can also be more susceptible to single-point failures if the master device goes down.

In short, CAN bus is a great choice for applications that require robust, real-time communication in a limited area, while PROFIBUS is better suited for larger, more complex automation systems. Consider your specific needs and requirements carefully when making your decision.

PCS7 Training Plant Bus And Terminal Profibus Versus

Real-World Applications

4. Where They Shine

So, where do these technologies actually show up in the real world? CAN bus is a workhorse in the automotive industry, connecting everything from engine control units to anti-lock braking systems and airbag controllers. It's also widely used in medical equipment, industrial automation, and aerospace applications.

PROFIBUS is a dominant force in factory automation, process control, and building automation. You'll find it in manufacturing plants, chemical processing facilities, and even smart buildings, controlling everything from robots and conveyors to pumps and valves.

Think of a bottling plant. CAN bus might be used within a single machine to coordinate the movements of various components, while PROFIBUS might connect all the machines in the plant, allowing them to communicate with a central control system. The two technologies can even be used together in a hybrid configuration to leverage their respective strengths.

The choice really boils down to the specific requirements of the application. Understanding where each technology excels can help you make the best decision for your needs.

Wat Is PROFIBUS En Hoe Werkt Het? Blog Igus® Nederland

Making the Right Choice

5. Choosing Wisely

Okay, so you've got a good handle on what CAN bus and PROFIBUS are all about. But how do you actually choose the right one for your project? Here are some key factors to consider:

Data Rate and Bandwidth: How much data do you need to transmit, and how quickly? CAN bus typically offers lower data rates than PROFIBUS.Network Size and Topology: How many devices will be on the network, and how far apart will they be? PROFIBUS is more scalable and flexible in terms of network topology.Real-Time Requirements: How critical is it that data is transmitted in real-time? CAN bus is generally better suited for real-time applications.Cost: How much are you willing to spend on hardware and software? CAN bus is typically less expensive than PROFIBUS.Complexity: How complex is the system you're building? CAN bus is generally simpler to implement than PROFIBUS.Don't be afraid to consult with experts and conduct thorough testing before making a final decision. There are also specialized gateway devices that allow CAN bus and PROFIBUS networks to communicate with each other, so you're not necessarily locked into one technology or the other.

Ultimately, the best choice is the one that meets your specific needs and requirements in the most cost-effective and reliable manner.

FAQ

6. Your Questions Answered

Still have questions? Here are some common queries to help you further clarify the differences between CAN bus and PROFIBUS.

Q: Can I use CAN bus and PROFIBUS together in the same system?A: Absolutely! Gateways can translate between the two protocols, allowing them to coexist and share data. This is useful when you want to leverage the strengths of both in different parts of a larger system.

Q: Which is easier to troubleshoot, CAN bus or PROFIBUS?A: It depends. CAN bus, being simpler, can sometimes be easier to diagnose basic connectivity issues. However, PROFIBUS often has more advanced diagnostic tools available due to its complexity, which can help pinpoint more intricate problems once you understand how to use them.

Q: Is one more secure than the other?A: Neither CAN bus nor PROFIBUS was originally designed with strong security in mind. Both are vulnerable to eavesdropping and manipulation if not properly secured. Modern implementations are adding security features, but it's crucial to implement appropriate security measures at all levels of the system regardless of which bus you use.

Q: Which is better for robotics applications?A: It really depends on the specific robot and application! CAN bus is often used for internal communication within the robot itself (e.g., between the controller and the motor drives), while PROFIBUS might be used to connect the robot to a larger automation system.