Real Tips About What Does An Inverter Do On A Motor

Unlocking Motor Secrets

Ever wondered how a motor smoothly revs up from a standstill or changes speed without a jerky start-stop action? Chances are, an inverter is playing a key role behind the scenes. It's not just some fancy add-on; it's a pivotal piece of equipment that transforms the way motors operate. Think of it as a translator, turning standard AC power into something a motor can really groove with. The word inverter (noun) is crucial in this conversation; it's the thing doing all the work!

Before we dive deep, let's consider the basics. Motors are often designed to run at a fixed speed determined by the frequency of the electrical power supply. However, many applications need variable speeds — a conveyor belt that sometimes needs to run faster, a pump that should adjust to demand, or even a simple fan in your home. That's where the inverter swoops in to save the day.

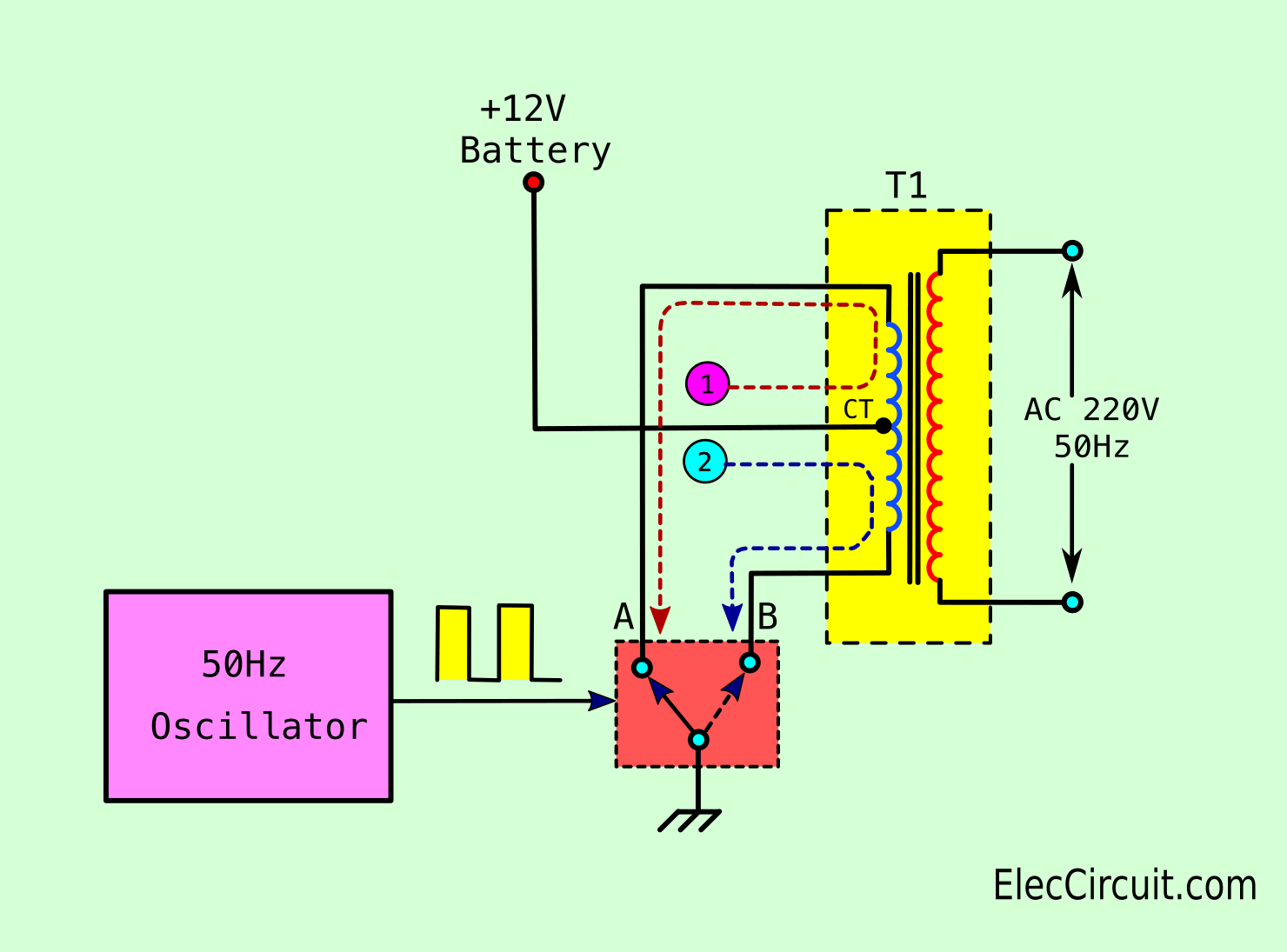

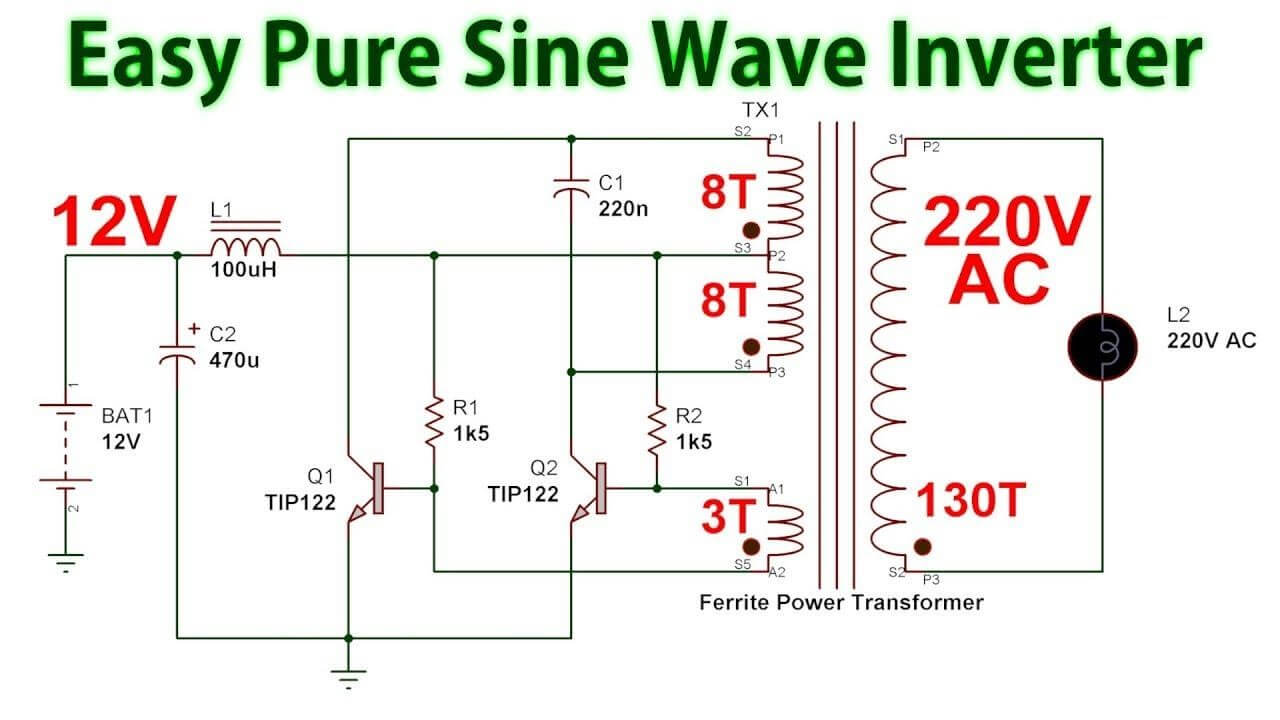

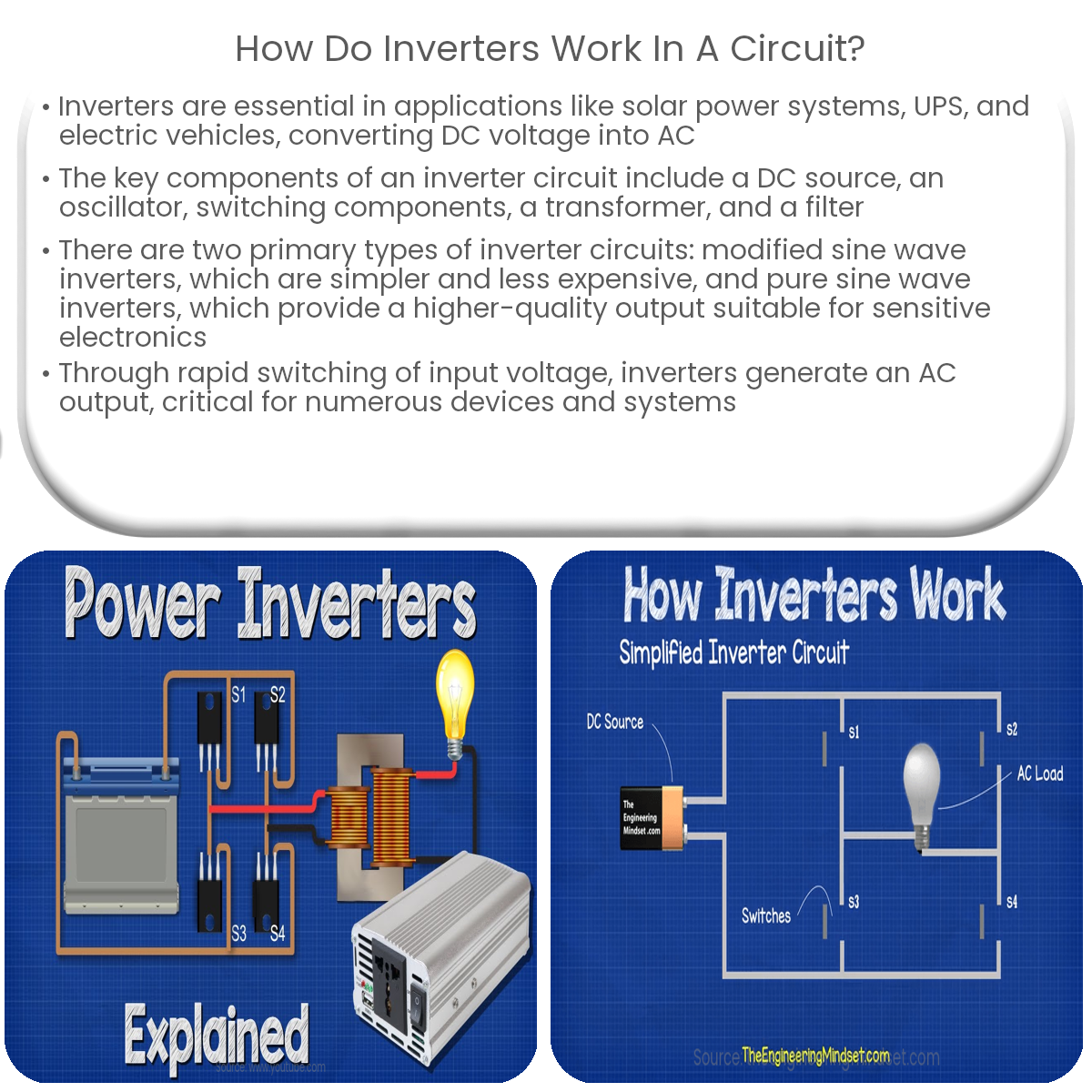

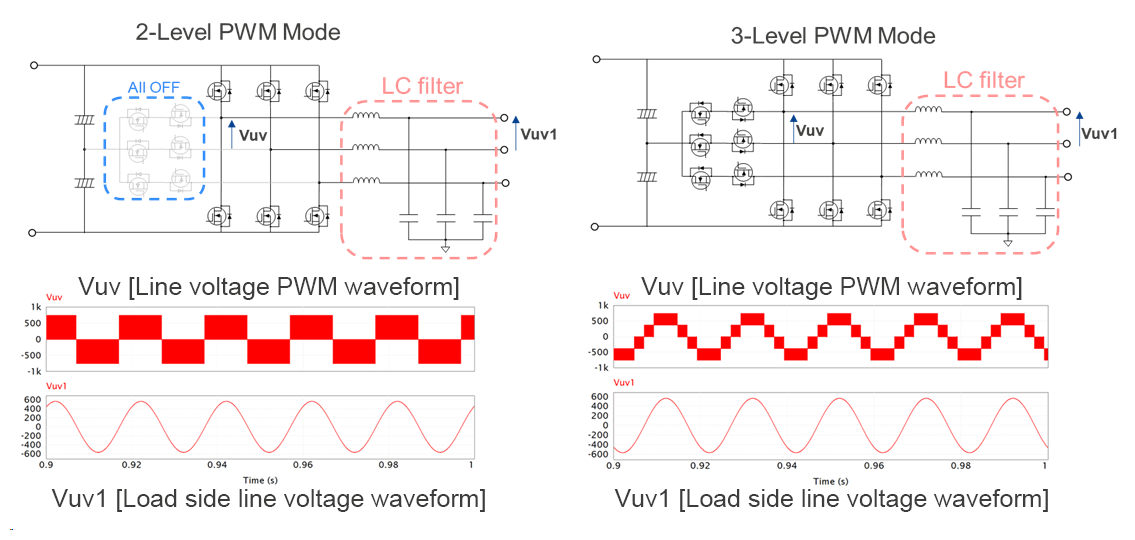

So, what exactly does an inverter do on a motor? Essentially, it provides a way to control the motor's speed and torque. It does this by converting the incoming AC (Alternating Current) power into DC (Direct Current) power, and then converting the DC back into AC, but at a different frequency. This altered frequency dictates how fast the motor spins. Pretty neat, huh? Think of it like changing the gears on a bicycle, but with electricity.

And it's not just about speed control. Inverters can also improve motor efficiency, reduce energy consumption, and even protect the motor from damage. They're like the responsible friend who ensures everyone has a good time without things getting out of hand. It's this control and efficiency that makes them so incredibly useful in a wide range of applications.

1. Why Speed Matters

At its heart, an inverter provides variable-frequency AC power to the motor. The original AC electricity from the wall outlet has a set frequency, say 60 Hz (in the US). The inverter cleverly modifies this frequency, allowing the motor to run faster or slower as required. Imagine a dial that lets you adjust the volume — the inverter provides a similar 'dial' for the motor's speed.

This variable-frequency drive (VFD) functionality opens up a whole new world of possibilities. Without an inverter, a motor typically runs at its designed speed, unless you use complex mechanical systems to change the output speed. An inverter offers a much more elegant and efficient solution, eliminating the need for belts, gears, or other cumbersome mechanisms. This also helps with the longevity of the motor since you can fine tune the power supplied to it.

Imagine a water pump. Without an inverter, it would run at full speed all the time, even when you only need a trickle of water. This wastes energy and can put unnecessary strain on the pump. With an inverter, the pump only runs as fast as it needs to, saving energy and extending its lifespan. It's like having cruise control for your water pump!

Think about it in terms of a car. A regular motor is like having only one gear. An inverter is like having a full transmission, allowing you to accelerate smoothly and efficiently. The end result is greater control, better performance, and reduced wear and tear. This means that using an inverter provides much better control, while also improving the motors performance and reduces wear and tear.

Wiring A Rotary Phase Inverter

Energy Savings and Efficiency

2. The Environmental Impact of Inverter Technology

Beyond speed control, inverters are champions of energy conservation. By allowing motors to operate at their optimal speed for the required task, inverters significantly reduce energy waste. Traditional motor control methods often involve throttling or damping, which dissipate excess energy as heat. Inverters, on the other hand, dynamically adjust the power supply to match the motor's needs.

Consider a large industrial fan. If it runs at full speed all the time, it consumes a significant amount of energy, even when the airflow demand is low. An inverter allows the fan's speed to be adjusted based on the actual ventilation requirements, reducing energy consumption by as much as 50% in some cases. That's a huge difference, both for your electricity bill and the environment.

It's not just about large industrial applications. Even in smaller systems, such as HVAC (Heating, Ventilation, and Air Conditioning) systems in homes and offices, inverters contribute to significant energy savings. By precisely controlling the speed of the fan and compressor motors, inverters optimize the system's performance and minimize energy waste. This can also lead to a more consistent and comfortable indoor environment.

Furthermore, reducing energy consumption translates to a smaller carbon footprint. By using less electricity, businesses and individuals contribute to a more sustainable future. Inverters are, therefore, a key technology in the effort to combat climate change and reduce our reliance on fossil fuels. It's like giving your motor a green makeover!

Motor Protection and Longevity

3. Inverters

Inverters aren't just about speed and efficiency; they also play a vital role in protecting motors from damage and extending their lifespan. They can detect and prevent various electrical faults, such as overvoltage, undervoltage, overcurrent, and short circuits. It's like having a built-in safety net for your motor.

One common issue that inverters address is voltage surges. These sudden spikes in voltage can damage the motor's windings and insulation. Inverters can quickly detect and suppress these surges, preventing costly repairs or replacements. They also protect against undervoltage conditions, which can cause the motor to overheat and fail.

Another important protection feature is overcurrent protection. If the motor draws too much current, it can overheat and damage its components. Inverters can limit the current to a safe level, preventing damage and extending the motor's lifespan. They also protect against short circuits, which can cause severe damage and even pose a fire hazard. Think of them as little electrical bodyguards for your machinery.

By providing these protection features, inverters not only reduce the risk of motor failure but also minimize downtime and maintenance costs. This translates to increased productivity and profitability for businesses. They help your motors live longer, healthier lives, reducing waste and saving you money in the long run. So, they protect your motor and improve you company's bottom line!

How Do Inverters Work In A Circuit? Electricity

Applications Across Industries

4. Versatility of Inverters in Various Sectors

Inverters are incredibly versatile and find applications in a wide range of industries. From manufacturing and agriculture to transportation and energy, inverters are essential components in many systems. Their ability to control motor speed and torque, improve energy efficiency, and protect motors makes them invaluable in a variety of settings.

In manufacturing, inverters are used in conveyor systems, pumps, fans, and machine tools. They allow for precise control of speed and torque, optimizing production processes and reducing energy consumption. In agriculture, inverters are used in irrigation systems, ventilation systems, and other equipment to improve efficiency and reduce operating costs. They are also used in electric vehicles to control the speed and torque of the electric motor, providing smooth acceleration and efficient energy use. In HVAC systems, inverters are used to control the speed of fans and compressors, optimizing system performance and reducing energy waste.

In the energy sector, inverters are used in renewable energy systems, such as solar and wind power, to convert DC power into AC power that can be fed into the grid. They also play a crucial role in grid stabilization and power quality control. The fact that they can be used in so many industries that can increase performance and reduce energy waste makes them very important.

Basically, wherever there's a motor, there's a potential application for an inverter. Their adaptability and versatility make them a cornerstone of modern industrial and commercial systems. It's safe to say that these applications ensure increased productivity and profitability. They're the unsung heroes of the modern world, quietly working behind the scenes to keep things running smoothly. From your refrigerator to a massive factory, inverters are making a difference.

Choosing the Right Inverter

5. Making an Informed Decision on Inverter Selection

Selecting the right inverter for a specific application involves careful consideration of several factors. The motor's horsepower, voltage, and current requirements are essential parameters. You also need to consider the application's specific needs, such as speed range, torque requirements, and environmental conditions.

When choosing an inverter, it's important to consider the type of motor it will be controlling. Different types of motors, such as induction motors, synchronous motors, and permanent magnet motors, require different types of inverters. It's also crucial to consider the control method used by the inverter. Common control methods include scalar control, vector control, and direct torque control. Each method has its advantages and disadvantages, depending on the application.

Furthermore, it's essential to consider the inverter's protection features. Overvoltage protection, undervoltage protection, overcurrent protection, and short circuit protection are all important features to look for. The inverter's operating environment is also a crucial factor. Temperature, humidity, and altitude can all affect the inverter's performance.

Finally, it's advisable to consult with an experienced engineer or supplier to ensure that you select the right inverter for your application. This can prevent costly mistakes and ensure that the inverter meets your specific needs. It is important to do your research and select an inverter that is compatible and will meet the needs of the motor. Choosing the wrong inverter can affect a motor and possibly have dangerous outcomes. So, always do the research.